FUEL INJECTION

We are authorized and qualified service technicians for diesel fuel injection pumps.

We can test, recalibrate, clean and service most makes and models of

injection pumps. All pumps include the latest updated parts and be brought up to the last factory specifications.

You can choose to buy one off of our shelf , or you can have your rebuilt with new the parts that have failed.

Stanadyne’s complete line of diesel fuel pumps powers the world’s engines. Designed for engines ranging in power from 5 BHP to 40 BHP per cylinder (3.7kW to 30kW per cylinder), these reliable, low cost, diesel fuel pumps are the standard in today’s most challenging applications.

- Denso

- Bosch

- Cummins PT

- Cau Lucas

- Stanadyne

- Delphi

- Cat Heui

- Ambac

- Kiki – Zexel

- Yanmar

Stanadyne

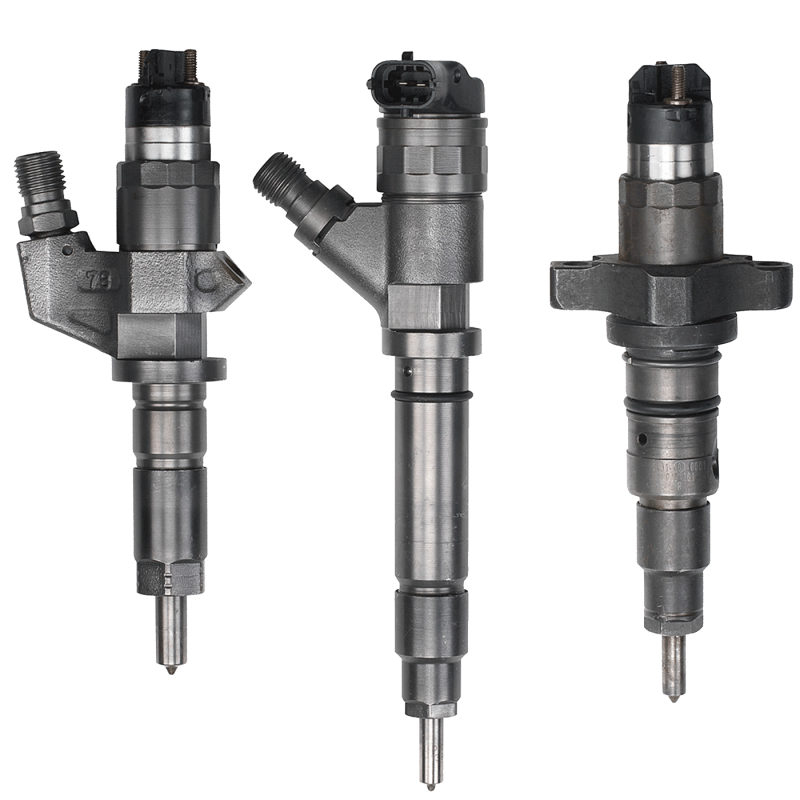

Stanadyne offers the widest selection of diesel fuel injectors available on the market today — from the proprietary Pencil Nozzle pioneered by Stanadyne to the industry standard 17 mm and 21 mm conventional size injectors. Engine applications range from 10 to 300 hp.

Pencil Nozzle

Diesel engine manufacturers worldwide have recognized Stanadyne’s Pencil Nozzle for its unique small size. The compact design allows the engine manufacturer design flexibility in the placement of cylinder head water jackets and valves as well as optimizing injector location within the combustion chamber. The resulting design helps engine manufacturers to meet the increasingly stringent emissions standards.

Features & Capabilities

- 9.5 mm Holder body diameter

- Nozzle shank diameters as small as 5.4 mm

- Rated for applications with peak injection pressures up to 1800 bar

- Opening pressures to 400 bar

- Low sac volume configurations

- Clamp style mounting

- Leak-off and No Leak-off versions

- Orifice conditioning for atomization optimization and tighter flow band tolerancing

- Injection Rate Shaping (RSN) feature available

Injectors Assemblies

Stanadyne provides a wide range of 17 mm and 21 mm injectors tailored to the engine manufacturers application and installation requirements in the M, P or S size configurations.

Features & Capabilities

- 17 mm, 17/21 mm and 21 mm Holder body diameters

- Nozzle shank diameters as small as 7.2 mm

- Rated for applications with peak injection pressures up to 1800 bar

- Opening pressures to 400 bar

- Low sac volume configurations including VCO

- Various engine mounting and leak-off arrangements available

- Orifice conditioning for atomization optimization and tighter flow band tolerancing

- Beginning of Injection sensor (BOI), lower valve guide and injection Rate Shaping

- (RSN) features available

Compact Pencil Nozzle

Stanadyne has recently developed the Compact Pencil Nozzle for smaller, high-speed, diesel engines. The CPN is the smallest injector currently available on the market. The CPN capitalizes on Stanadyne’s years of injector development experience and incorporates recent advances in manufacturing technology. This blend of design and manufacturing technology results in an innovative, cost competitive alternative to standard industry products.

Features & Capabilities

- 9.5 mm Holder body diameter

- Nozzle shank diameters as small as 5.4 mm

- Rated for applications with peak injection pressures up to 1800 bar

- Opening pressures to 400 bar

- Low sac volume configurations including VCO

- Clamp style mounting

- Leak-off and No Leak-off versions

- Orifice conditioning for atomization optimization and tighter flow band tolerancing

- Injection Rate Shaping (RSN) feature available

- Improved spray pattern orientation in engine

Nozzle Assemblies

A wide variety of nozzle assemblies are available to OEM engine designers to meet their specific application requirements. Nozzle design, spray patterns and flow requirements are closely coordinated with the engine manufacturer to serve his performance requirements.

Rate Shaping Nozzle

Stanadyne has developed the RSN feature to assist engine manufacturers meet the increasingly stringent emissions standards, achieve combustion noise reductions and improve low speed light load stability. The RSN incorporates an innovative and cost competitive approach to fuel injection rate shaping. This feature can be incorporated into either Stanadyne’s Pencil Nozzle or conventional size injectors.

Features & Capabilities

Production proven engine emissions, combustion noise reduction and low speed light load stability

Greater injection rate control potential than the industry common two spring (TSI) approach

Physically interchangeable with current injector size and application configurations

More stable performance over the life of the product than the TSI due to its non-contact operation

More uniform spray characteristics due to the lower guide feature